Welding has unbound applications. Actually it is very tough to find out any sector from aeronautic to automotive, building construction to industrial works everywhere welding is a must. It has the most practical utility in real life. Welding ensures service at low cost, low weight, high strength and rigidity.

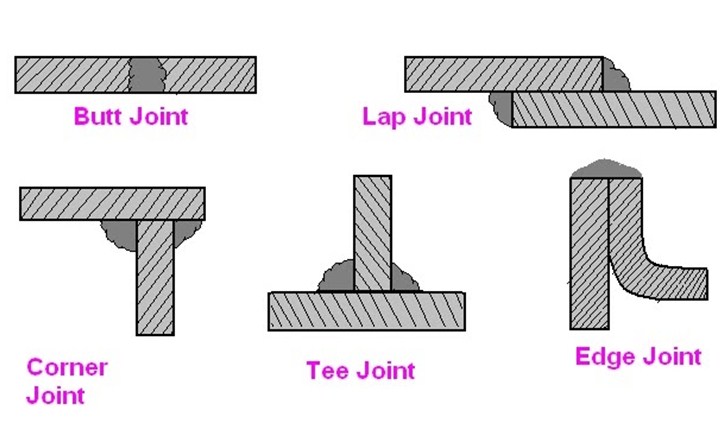

The main task of welding is to join two or more things. But all types of joints are not the same as they are produced for different purposes. There are five basic joints of welding. The welders must be careful about these five joints to get the best result.

To know more about the welder and welding process, view on this website.

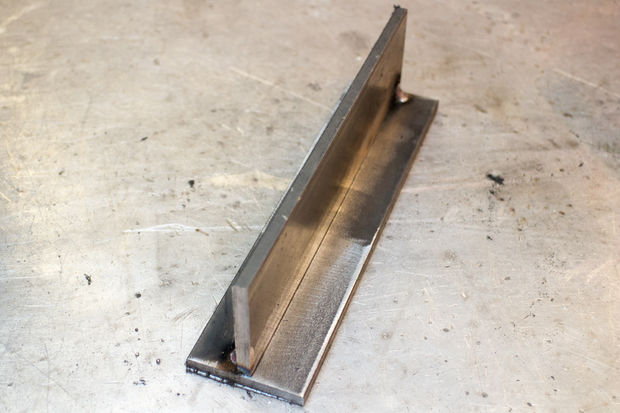

Tee joint

When two metals intersect at 90-degree angle a tee welding joint is formed. In that process, the edges are centered of a plate or component. Tee joints are as similar as fillet weld. It can also be done when a tube of a similar pipe is welded to a base or plate. You have to be very careful to confirm effective penetration.

Lap joint

Lap joints are mostly used for different thickness metals. This type of joints is also a fillet type which has options to weld from both sides. A lap joint is usually done when 2 pieces of metals are placed in the pattern of overlapping on top of each other.

Joint making for edge welding

Edge welding is mostly done for sheet metals where flanging edges are placed for joining adjacent pieces of metal. As the welding is done into the grooves, the pieces are set one after another aside and welded on the same edge. If you want to apply it for heavier purposes, filler metal has to be added for melting the edge perfectly to reinforce the plate.

Welding for corner joint

Corner joint is very important as it is widely used in the sheet metal industry. It is basically used in the outer edge of a metal piece. It is such type of welding that creates 90⁰ angel between the two metals and forms like an L. This type of welding is specially used to make rectangular and square shapes like boxes, frames of boxes. Similar kinds of fabrications also done by corner joint welding.

Butt joint

Butt joints are specially used to join pipes or anything like that. For joining valves, fitting, flanges and similar kinds of equipment are used for butt welding. We also know that another name of butt welding joint square grove weld. At present, it is considered as the easiest type of welding. In it, two flat pieces of metals are kept parallel side by side. As a client for welding activities, you can consider it as an affordable one.

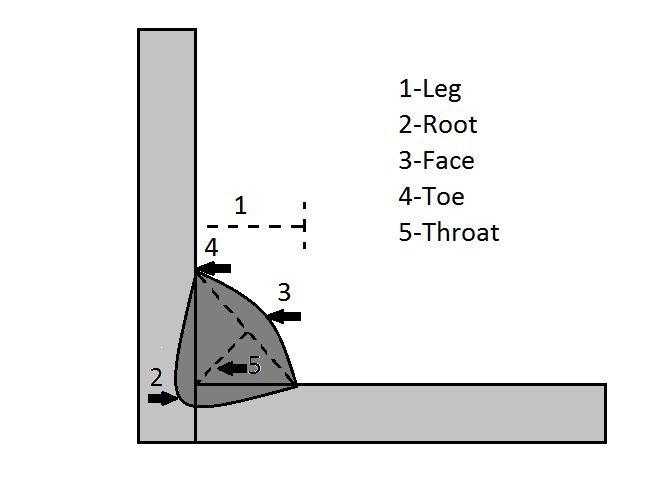

Fillet welding joint

This type of joints is actually the alternative of the lap, corner, and tee joints. A fillet is the most common welding joints which are made with arc welding. You do not need to prepare the edges for this welding. Fillet welding is cheaper than butt welding. To join a pipe with any socket, Fillet welding is used widely.

Whether you want to be a welder or is a client of welding, you should have ample knowledge about the joining of welding. It will help you to do the work perfectly with great expertise.